JUSTSEN Saturated Steam Boilers

We offer a large range of JUSTSEN Saturated Steam Boilers to suit individual client needs with regards to capacity, temperature, pressure, fuel, emission standards and automation.

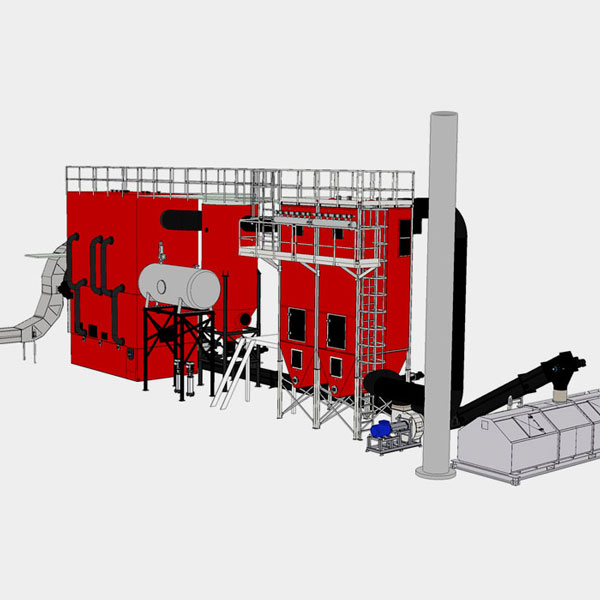

High Pressure Steam Boiler type JUE-TDC-F

Capacity up to 50 t/h. Designed for versatility as the combustion system can be adapted for all types of biomass fuels. The boiler consists of a separate grate/radiation section, a horizontal steam drum with flue gas tubes and a vertical flue gas economizer. The boiler is available in both high pressure hot water and saturated steam versions.

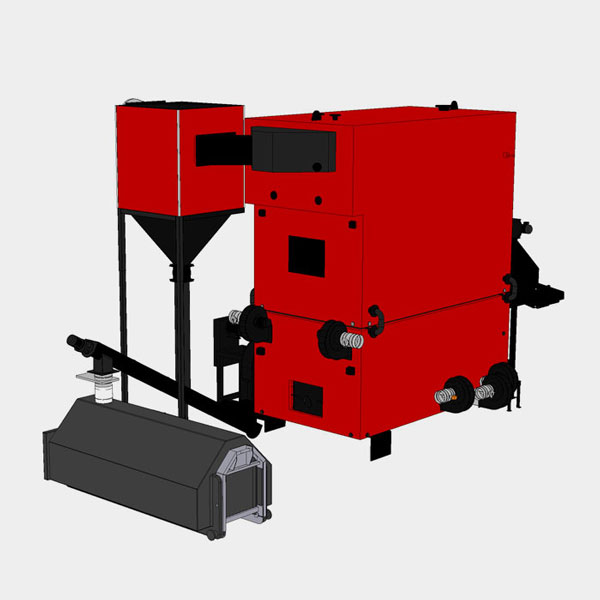

High Pressure Steam Boiler type JUE-DHF

Capacity up to 16 t/h. Designed for versatility as the combustion system can be adapted for all types of biomass fuels. The boiler consists of a grate/radiation section with a horizontal steam drum. Vertical flue gas economizer is optional. The boiler is available in both hot water and steam versions.

Low Pressure Steam Boiler type JUE-MMD

Capacity up to 8 t/h. Designed for versatility as the combustion system can be adapted for all types of biomass fuels. The boiler consists of a grate/radiation section with a horizontal convection drum. Built-in horizontal flue gas economizer is optional.