Biomass Fueled Boiler Systems – Renewables

Justsen Energiteknik A/S is an original equipment manufacturer (OEM) specializing in biomass fueled boiler systems. We work through our technical partners in selected markets and together we deliver complete biomass boiler plant projects and after sales support. With our long-lasting partnerships worldwide, we have been able to carry out most complex projects successfully and have been doing so for sixty years.

Justsen Subsidiaries

In addition to our worldwide network of technical partners, we have also chosen to directly establish or invest in selected companies.

Justsen Pacific in Sydney

Euro Therm

Justsen Pacific in Sydney

Established in 2017, Justsen Pacific is the Asia Pacific presence of Justsen Energiteknik. We combine Australian heritage and presence with the technical knowledge and distinguished reliability of Danish manufacturing, enabling us to deliver dependable, economical, and advanced bio-energy boiler capability.

Euro Therm

In July of 2019, company Euro Therm A/S, a biomass boiler manufacturer and turnkey solutions supplier, filed for bankruptcy. An executive decision was made at Justsen Energiteknik A/S to take over and revive the company. Justsen acquired all Euro Therm assets, including service engineers and equipment. Euro Therm is a fully owned subsidiary of Justsen.

Message from the CEO

Over 60 Years of Continuous Development and Innovation

Founded in 1959, Justsen has become a top-quality biomass fueled boiler systems producer in the global market. We are convinced that a great deal of our success is based on developing partnerships the right way.

Therefore, our strategy is:

- to cooperate with the best companies around the world to promote and operate our bioenergy boilers;

- for our know-how to be recognized by all companies interested in reducing the carbon footprint;

- to maintain long-term relations with all our customers, making sure the performance and reliability are preserved during the lifetime of the boiler.

We are known for the best product and the best economy, calculated over the lifetime of the boiler, which proves Justsen technology to be an investment with a vision for the future.

We believe that it is our obligation to reduce the carbon footprint from industry and domestic heating by using renewable biomass. To further grow, we want to use ever more difficult biomass to reduce the waste going to landfills. We are strongly committed to protecting the forests by using only certified biomass or biowaste from production.

Going forward, Justsen will design and manufacture boilers that operate to the highest standard on emissions and efficiency, without ever compromising on quality.

Claus Justsen

Owner, Chairman of the Board

News from around the world

Heat for Greenhouses

Reference: Greenhouse Project Neame Lea

Location: Spalding, United Kingdom

Neame Lea is the UK’s leading ornamental plant supplier and a part of Bridge Farm Group. There are developed brand new state of the art glasshouses in several phases. These projects are realized together with a Dutch company KG Systems, specialists of turn-key greenhouse projects. Biomass boilers are used produce heat for the new glasshouses in Spalding. There are three 8 MW hot water boiler units and one 2.2 MW boiler in operation.

System Specification: Three 8 MW hot water boiler units and one 2.2 MW boiler.

Fuel: Wood chips.

District Heating

Reference: Straw Fired District Heating Plant Midtlangeland Fjernvarme

Location: Midtlangeland, Denmark

Upgrade of the existing boiler house required changing the old steam-based boiler to a new Justsen hot water boiler. The project was implemented together with Tjæreborg Industri. Total contract value is reported to be around 25 million Danish kroner. Justsen boiler components were delivered from Brabrand to the site in Midtlangeland in two parts.

System Specification: 7.7 MW hot water boiler designed for district heating technology.

Fuel: Straw from wheat, barley, rapeseed, rye, oats and other origin.

Heat and Power

Reference: CHP Plant “Rigas energija” Ltd

Location: Riga, Latvia

The purpose of ‘’Rigas energija’’ Ltd. plant is to produce electricity and provide heat for the district heating network in Riga using biomass of local origin, thus contributing to the economy. The construction works were performed by „Latvijas Energoceltnieks” Ltd.

System Specification: The electrical capacity 4.4 MWe and the thermal capacity 20 MW.

Fuel: Wood chips.

Steam for Textile Industry

Reference: Textile Industry Giant’s Gildan Plants

Location: Rio Nance, Honduras

Gildan is a leading Canadian multinational company that manufactures high-quality basic clothing, with production facilities in the Dominican Republic and Honduras. Its industrial activity requires a high saturated steam flow. This used to be produced by heavy oil boilers, which drove the company to face high energy costs and resulted in a larger carbon footprint.

System Specification: Six 25t/h steam boilers, 16 bar(g) design pressure.

Fuel: A mixture of different types of biomass is used as fuel, including waste from the plant’s own processes, African palm byproducts, king grass from energy crops, and wood sawdust.

Steam for Food Industry

Reference: Canola Oil Producer’s MSM Milling Plant

Location: Manildra, New South Wales, Australia

The project was implemented through our subsidiary in Australia, Justsen Pacific Pty Ltd. MSM Milling is a canola oil producer and uses steam for oilseed processing operations. According to the Australian Renewable Energy Agency (ARENA), the project is one of the first demonstrations of a large-scale food manufacturing company in Australia using biomass for thermal energy to reduce their costs and environmental impact.

System Specification: 7,147 kg/h steam boiler system, design pressure 16 bar(g).

Fuel: Wood chips mixed with grindings, wood fines, sawdust, and bark.

Biomass for Biogas

Reference: Biomass Plant for the Biggest Biogas Plant in North Jutland

Location: Grøngas Vrå, South of Hjørring, Denmark

In 2015, Justsen delivered a straw-fired boiler to the biggest biogas plant in North Jutland – Grøngas Vrå. The overall territory of the plant is 87,000 square meters which correspond to the size of twelve football fields. The biogas plant mainly produces biogas from local manure, industrial waste products, and food residues.

System Specification: 7 MW hot water boiler, design pressure 6 bar(g).

Fuel: 2015 – 2018 straw bales (Heston) and from 2018 olive crops.

Heat for Wood Processing Industry

Reference: Windows and Doors Manufacturing Complex

Location: Marijampole, southern Lithuania

The manufacturer has made huge investments in their production facility in Lithuania, thus, potentially becoming the largest manufacturing complex in Lithuania, as reported by Baltic FEZ. Byproduct of the manufacturing process classified as biomass is used to fuel the boiler and supply heat for the factory. The project was implemented in collaboration with Justsen’s local technical partner New Heat Group.

System Specification: Two ARGUS Flex series hot water boiler systems with max. heating output respectively 2.4 MW and 1.35 MW. Design pressure 4 bar(g).

Fuel: Granulated chip board, sawdust and wood pellets.

Steam for Beverage Industry

Reference: Soda Drinks Producer’s Kangshifu Plant

Location: Wuhan, Hubei Province, China

The end-user is a Chinese beverage producer, and the steam is used to produce soft drinks. This project was implemented as a pilot project. Justsen delivered all main boiler system components, provided on-site supervision and schooling. This new combustion technology reduces emissions and contributes to cleaner air and a blue sky.

System Specification: Two 25 t/h high-pressure steam boiler systems.

Fuel: A mixture of wood chips, bark, and sawdust, all classified as biofuel.

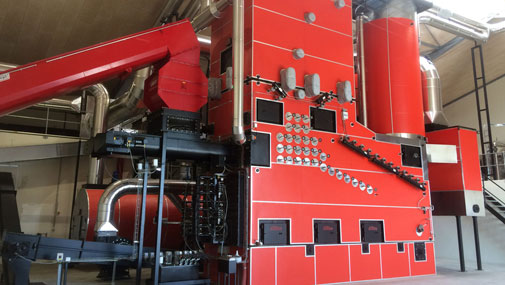

Justsen Biomass Fueled Boiler Systems

Hot Water Boilers

We offer a large range of JUSTSEN Hot Water Boilers to suit individual client needs with regards to capacity, temperature, pressure, fuel, emission standards and automation.

Saturated Steam Boilers

We offer a large range of JUSTSEN Saturated Steam Boilers to suit individual client needs with regards to capacity, temperature, pressure, fuel, emission standards and automation.

Superheated Steam Boilers (CHP)

We offer a range of superheated steam boilers. Their purpose is primarily for operation with steam turbines to produce electricity with residual thermal energy as either hot water or saturated steam. They are all bespoke boilers optimized to suit individual client needs with regards to capacity, superheated steam temperature, emission standards and automation.

Boilers for Organic Rankine Cycles (ORC)

We offer a range of superheated steam boilers. Their purpose is primarily for operation with steam turbines to produce electricity with residual thermal energy as either hot water or saturated steam. They are all bespoke boilers optimized to suit individual client needs with regards to capacity, superheated steam temperature, emission standards and automation.

Renewables (WID/IED)

We offer bespoke solutions for using waste as fuel, such as contaminated wood waste. Justsen WID/IED boilers can be designed for hot water or saturated steam as described under those headings.

ARGUS Standardized Hot Water Boilers

We offer two standardized boiler lines under the ARGUS brand. Please inquire for technical data sheets.

System Elements (OEM)

Justsen designs and manufactures a large range of system elements to be used in connection with fuel handling and energy systems. The equipment is designed to the same high standards and build quality as all other products under the Justsen brand.

After Sales

Basic Support

Free telephone support and discounts on original Justsen spare parts sent in 1-2 business days.

Service Plus

Includes two annual site visits. We highly recommend our customers to enter a Service Plus Agreement to fully benefit from the boiler servicing options.

10 Years Extended Warranty

Extend your standard warranty by one year at a time for up to 10 years. Special conditions apply.

Remote Alarm Service

Get notified via SMS about any potential alarms in your boiler room. Requires Support or Service Plus Agreement.

Emergency Box

Own all strategic spare parts and wear and tear parts for your boiler. Purchasing Emergency Box is possible either after 2 years of standard warranty or at any given time.